our approach aimed at maximizing productivity & efficiency.

Founder, SH Turnstile Factory.

modern ways of manufacturing products.

Modern manufacturing is a blend of advanced technologies and streamlined methodologies. Key concepts and techniques include:

- Automation and Robotics: Robots and automated systems handle repetitive, high-precision tasks, minimizing human intervention, increasing efficiency, and lowering labor costs. This is often part of Industry 4.0, or “smart manufacturing,” which integrates information technology with operational technology.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD software is used to design products digitally, while CAM systems guide computer-controlled machines (like CNC machines) to manufacture the parts with high precision and consistency.

- Precision Machining: CNC (Computer Numerical Control) machines, along with other advanced tools like laser cutters, are used to form and shape materials with extreme accuracy, reducing waste and ensuring high-quality components.

- Additive Manufacturing (3D Printing): While not used for all components, 3D printing is valuable for creating prototypes, specialized parts, and complex geometries with minimal waste.

- Joining and Assembly: Techniques like laser welding, automated fastening, and robotic assembly are used to join components with strength and precision.

- Advanced Materials and Coatings: Manufacturers use materials like durable stainless steel (e.g., 304 or 316) for its weather resistance and strength. Modern coating processes like powder coating provide a durable, rust-resistant, and aesthetically pleasing finish.

- Lean Manufacturing: A methodology focused on maximizing efficiency by reducing waste in all aspects of the production process, from materials to time.

Manufacturing a Swing Barrier Turnstile

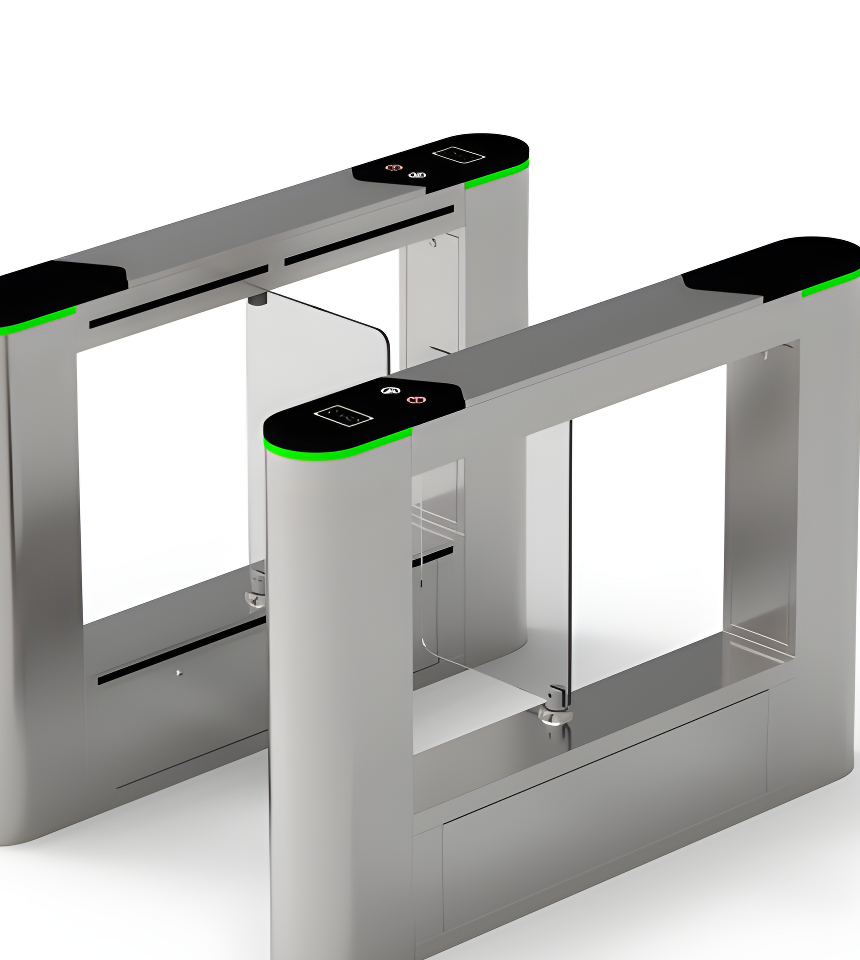

A swing barrier turnstile is a modern access control solution characterized by a single or double swinging arm or panel, designed to provide efficient and aesthetic pedestrian control, often accommodating wider passage for accessibility. Its manufacturing process leverages the same advanced techniques and principles as other contemporary turnstile systems, ensuring a durable, reliable, and intelligent product.

1. Design and Prototyping (CAD & 3D Printing):

The manufacturing process commences with the meticulous design phase, heavily utilizing CAD (Computer-Aided Design) software. Engineers develop comprehensive digital models of the swing barrier turnstile, including its elegant chassis, the sophisticated swinging arm mechanism, and the intricate internal electronic architecture. This digital environment facilitates extensive virtual simulations, stress analysis, and design optimization to ensure structural integrity, smooth operation, and aesthetic appeal. For complex mechanical linkages or to validate specific design elements and ensure precise fit, 3D printing may be employed to generate rapid prototypes for quick physical assessment and iterative refinement.

2. Component Manufacturing (Precision Machining & Forming):

The core components of the swing barrier turnstile are fabricated using a diverse array of modern, high-precision manufacturing techniques:

- Chassis: The sleek outer casing, typically constructed from high-quality stainless steel (e.g., 304 or 316), undergoes precise cutting using CNC laser cutting machines. This ensures sharp, clean edges and exact dimensional accuracy. The cut metal sheets are then expertly bent and formed into the final ergonomic shape using automated presses or bending machines, guaranteeing robust structural integrity and a refined finish.

- Swinging Arms/Panels: The defining feature, the swinging arm or panel, is manufactured for both durability and smooth motion. These are often made from tempered glass, high-strength acrylic, or stainless steel. They are precision-cut (e.g., CNC cutting for glass, laser cutting for acrylic/metal) and carefully shaped. The pivot points, hinges, and connection hardware for these panels are manufactured with exceptional precision through CNC machining, ensuring quiet, fluid, and reliable swinging operation.

- Mechanism: The “powerhouse” of the swing barrier—the electromechanical assembly responsible for the controlled opening and closing of the arm—is engineered for high performance and longevity. Its internal components, including specialized high-torque motors, robust gears, drive shafts, and linkage systems, are meticulously processed by CNC machine tools. This precision manufacturing ensures ultra-high levels of accuracy, minimal wear, silent operation, and an extended service life.

3. Integration of Electronics and Control Systems:

The “smart” capabilities that define a modern swing barrier turnstile are derived from its advanced electronic control system, a vital stage in its contemporary manufacturing:

- PCBs (Printed Circuit Boards): The sophisticated drive control boards and other electronic modules are produced on high-precision automated assembly lines. Robotic systems accurately place and solder miniature electronic components onto the circuit boards, guaranteeing consistent quality and performance.

- Sensors and Logic: The turnstile’s intelligent functionality relies on a network of multiple infrared sensors that precisely detect pedestrian presence, direction, and potential unauthorized access attempts (like tailgating). The central control system processes these signals and commands from integrated access control devices (such as biometric scanners, RFID readers, QR code readers, or push buttons). The intricate wiring and modular integration of these electronic components are meticulously planned for efficient assembly, reliable operation, and ease of future maintenance.

- Software: The turnstile’s firmware and operational software, which include complex algorithms for pedestrian flow management, anti-tailgating protocols, lane indicators, and critical emergency functions (e.g., automatic opening for evacuation), are precisely programmed and loaded onto the control board, enabling its full range of “smart” functionalities.

4. Assembly and Joining (Robotics & Manual Assembly):

The final assembly phase meticulously brings together all the manufactured components into a cohesive unit:

- The precisely engineered swinging mechanism, including the motors and drive systems for the arms, is carefully mounted and calibrated within the turnstile chassis.

- The swinging arms or panels are securely attached to their pivot points and integrated with the mechanism, ensuring smooth, unobstructed movement.

- The electronic control board, power supply, sensors, and all other electrical components are meticulously wired, connected, and secured inside the chassis, often using modular designs for accessibility and ease of service.

- While robotic systems are increasingly utilized for repetitive fastening, welding, and precise component placement, some intricate assembly steps, particularly those requiring fine mechanical adjustments or delicate wiring, may still involve highly skilled human technicians.

5. Finishing and Quality Control:

The concluding steps are paramount to ensuring the product’s durability, visual appeal, and operational excellence:

- Coating: For stainless steel or other metallic components, processes like powder coating are applied. This involves electrostatically charging and spraying a dry powder onto the metal surface, which is then heat-cured to form an extremely hard, chip-resistant, and corrosion-proof finish, significantly enhancing both protection and aesthetics.

- Testing: Every single swing barrier turnstile undergoes a comprehensive and rigorous battery of tests.1 Automated testing systems simulate thousands upon thousands of operational cycles, verifying the mechanism’s responsiveness, the accuracy of the sensors, the reliability of the control system, the speed and smoothness of the swinging motion, and noise levels. This exhaustive “no-fault” testing regime ensures that each turnstile meets its demanding operational lifespan requirements, safety standards, and performance specifications before it leaves the factory.

Precision for Smooth and Quiet Motion

The manufacturing process prioritizes high-precision engineering to achieve the swing barrier’s smooth and quiet operation.

- CNC Machining: Critical components like pivot points, hinges, and the internal drive mechanism are created with CNC machine tools to ensure perfect alignment and minimal friction.

- Specialized Mechanism: The turnstile uses a sophisticated electromechanical drive system with high-torque motors to control the swinging motion, ensuring it opens and closes fluidly without noise or sudden movements.

Advanced Electronics for Smart, Accessible Control

The swing barrier is defined by the integration of advanced electronics, which makes it a smart and versatile access solution, particularly for accessibility.

- Network of Sensors: The system relies on multiple infrared sensors to accurately detect pedestrian presence and direction, which is essential for managing the swinging motion and preventing collisions.

- Sophisticated Software: The control board is loaded with advanced firmware and algorithms to handle features like anti-tailgating logic, pedestrian flow management, and crucial emergency functions, such as automatically opening the barrier for a wide, accessible path during an evacuation.

service related FAQ’s

We use 1.5 mm thick 304 and 316-grade stainless steel.

It takes around three business days to complete a sample order, and around 7–10 days for a bulk order. However, you’ll also need to wait for it to arrive from China.

The warranty period lasts three years from the date of delivery, and it covers all products purchased from SH Turnstile. Once the warranty expires, you’ll have lifetime maintenance, courtesy of SH Turnstile.

Yes. We make bi-directional turnstiles, as well as one-way passage turnstiles.

Yes, our swing turnstiles come with infrared sensors. With 1200 mm turnstiles, you’ll get three sensors; with 1600 mm turnstiles, you’ll get five. In case you require more than that, contact us, and we’ll work something out.